Types of UHF RFID Passive Tags and How They Are Used

RFID (Radio Frequency Identification) technology has become an integral part of numerous industries, offering efficient and reliable tracking and identification solutions. Among the various types of RFID systems, UHF (Ultra High Frequency) RFID passive tags are popular for their versatility and range. These tags come in numerous forms to suit different needs and deployment environments. Let’s explore some of the most common types of UHF RFID tags and their applications.

Types of UHF RFID Passive Tags and How They Are Used

Explore different types of UHF RFID passive tags - including RFID labels, inlays, and RFID hard tags, to understand their unique applications in various industries. Discover how each type of RFID tag is unique created for specific use cases, environments, mounting materials, and even specific types of attachment.

Labels and Inlays

The most widely used UHF RFID tags are labels and wet inlays, known for their low cost and disposability. These tags can achieve an average read range of about 20 feet, making them ideal for many applications.

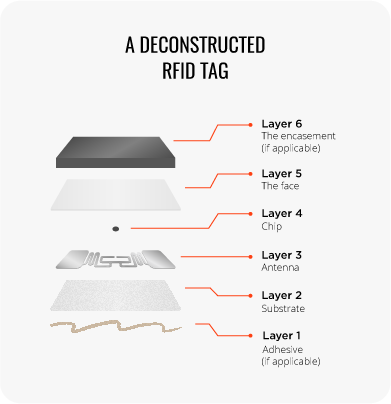

- Dry Inlays: These are the simplest form of RFID tags, consisting of a chip and a flat metallic antenna encased in a plastic or PET form. They lack adhesive backing, which makes them suitable for embedding into other items, such as custom price tags.

- Wet Inlays: These are essentially dry inlays with added adhesive, allowing them to stick to items easily. Wet inlays are prevalent for retail items, race timing bibs, and inventory or asset tracking. Their adhesive nature makes them versatile for numerous applications.

- Labels: These are wet inlays with a printable white surface, allowing for the addition of text, images, logos, or barcodes. Labels extend the usability of wet inlays, particularly when direct information printing is necessary.

- Metal-Mount Labels: Unlike regular RFID labels, metal-mount labels possess an additional metal backing. This design enables usage on metal objects, facilitated by specialized printers due to their greater thickness. They are particularly useful in IT asset tracking for electronics like servers and monitors.

Hard Tags

Hard tags are a more durable form of RFID tags, designed for specific applications requiring robustness against environmental elements.

- Form Factor: Hard tags can vary greatly in their shape and are created by encapsulating RFID inlays within protective shells. Examples include wristbands, cards, badges, and flag tags, which are tailored for specific uses such as access control and attendee tracking.

- Attachment Method: Some hard tags, such as laundry and hang tags, offer unique attachment methods suited for distinct applications. Laundry tags can be sewn into garments or placed in hems, making them useful in textile management.

- Mounting Material: Certain hard tags are designed for specific surface types, such as metal, wood, or glass. Glass-mount tags, for instance, are perfect for mounting on windshields for toll collection and access control.

- Ruggedness: Extremely rugged hard tags boast high IP ratings (67 and above), allowing them to withstand extreme conditions like high temperatures, impacts, and moisture. These tags are indispensable in challenging environments like mining and manufacturing, where durability is paramount.

The diversity in UHF RFID passive tags means there’s a solution for nearly every tracking requirement, from retail and logistics to more complex industrial needs. These tags ensure efficient and reliable data tracking, improving operational efficiency and asset management across various sectors.

Conclusion

For more insights into RFID technology and its applications, visit our blog, RFID Insider. Contact us for any inquiries or additional information on how RFID can benefit your operations.

You May Also Like

Let Us Help!

For more information on which tag is best for your specific application - schedule a call with one of our RFID experts.