RFID Tag Labels: How do I Determine the Ideal Size?

As discussed in our article A Tag, a Label, an Inlay, there are quite a few names for RFID tags that all have slight differences based on the verbiage and context. For instance, an RFID inlay is typically an RFID tag with adhesive that is clear, so you can see the chip and tag antenna clearly. In this article we are going to talk about RFID labels – RFID tags with a paper or plastic white face that can be printed on. RFID labels can also be called Smart Labels or White Wet Inlays.

When deciding the ideal RFID label for an application, size and label format are extremely important factors to consider. In this article we will walk through how to determine the ideal size for your RFID application so that you can narrow down your ideal RFID label.

RFID Label Sizes

There are three sizing categories that RFID labels are sold in – RFID tag size, standard sizes, and custom sizes.

RFID Tag Size Labels

RFID labels that are the same size as the RFID tag are the most commonly available size group. These labels usually come directly from the RFID tag manufacturer with a white paper or plastic face. The size of these RFID labels varies from short and thick like the Smartrac Web RFID Tag (2.13 x 1.30 in) to long and thin like the Beontag E64 Paper RFID Tag (4.29 x 0.39 in).

If your application needs a very specific tag without a large amount of printable area – this option is probably the best way to go. The specific amount of printable data would depend on the exact RFID tag chosen, but most of the time these tags have enough space for a small barcode and a line or two of human readable text, like the example below.

Standard Label Sizing

Certain RFID inlays are available in standard label sizes, which are most commonly 4”x 6” and 4” x 2”. These labels are created when manufacturers or label converters embed RFID tags into standard size label paper in order to allow for more space for printable data. These sizes correlate to a standard inventory label at 4”x 2” and a standard shipping label at 4”x 6”. Typically, the RFID inlay is embedded at the top or in the center of the label and programmed at the same time that the human-readable data is printed via an RFID printer.

The main difference between the two main standard sizes of 4”x 2” and 4”x 6” is the amount of room for printable data like barcodes, product/SKU information, and shipping information. A 4”x 2” label is ideal for inventory tracking, asset tracking, warehouse management and other RFID applications that need to be tracked and managed by RFID and visually identified with printable data. A 4”x 6” RFID label is ideal for logistics, transportation, pallet-level tracking and management, or any RFID application that additionally needs larger 1D and/or 2D barcodes in addition to printable data.

If your application needs an RFID tag with an average read range that is usually captured in a fixed location, and requires barcodes and a lot of human readable text, these labels might be the best. The large amount of space on the label will easily accommodate shipping information, product information, and multiple barcodes if required. The most common use case for these standard size RFID labels is for 3rd party suppliers to meet government or mandate requirements that specify labels must have a Gen 2 RFID tag with an average (specified) read range.

Custom Label Sizing

For RFID applications requiring a custom label size or shape, RFID tags can be embedded in a wide range of label sizes and materials in order to meet industry standards or application requirements. Converter machines can take dry RFID inlays and convert them into custom shapes, sizes, materials, and even attachment methods. For more information on the label customization process – contact us or take a look at our article - Customizing RFID Tags: Options You Need to Know.

How Label Sizing Affects Printability

Each RFID printer has a minimum and maximum RFID label length and width that is important to take into consideration when choosing a printer and/or RFID tag. Most printers on average have the following size guidelines for RFID labels:

- Minimum Width: 0.50” – 0.98”

- Maximum Width: 4.09” – 4.65”

- Minimum Length: 0.25” – 0.35”

- Maximum Length: 39” – 98”

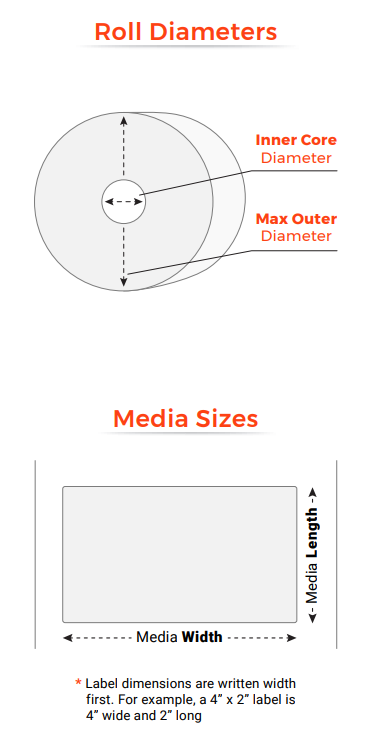

Two other important factors to consider when printing RFID labels of different sizes are the core size and outer diameter.

Core Size

RFID tag labels are available on rolls that can be placed in an RFID printer like the Zebra ZT411 or the SATO CL4NX. Each roll of RFID labels has a cardboard core at the center and that core size must fit on the printer’s spindle. Each printer’s spindle is a slightly different size so it’s important to double check an RFID tag roll’s core size before ordering. If the core size is too big or too small, the RFID labels can always be rerolled onto a different core size that fits your printer’s specifications.

Roll Outer Diameter

Exactly as it sounds, a roll of RFID tags has an outer diameter measurement that depends on the RFID label size and the number of labels on the roll. If a roll of tags is too large, it could mess with other parts of the printer or not allow the printer to close properly. Outer Roll Diameter, also called Roll Diameter Maximum is a specification labeled on each RFID printer’s data sheet and is important to consult when purchasing RFID labels for your RFID printer. If a roll of RFID labels exceeds the maximum outer diameter, the tags can be rerolled onto two different cores to create two smaller rolls.

Conclusion

For more information on how to properly choose the best RFID label size for your RFID application and RFID printer, contact us!