From Clipboards, To Barcodes, To RFID – The History of Supply Chain Management

Introduction

From its inception in 1908, through 1980 when the term “supply chain management” was coined, to now, there have been many steps in the evolution of the modern supply chain. The idea behind supply chain management is simple–cut costs associated with making and distributing a product by cutting inefficient steps in the process. Throughout the evolution of supply chain management, the ultimate goal remains the same, but the tools change.

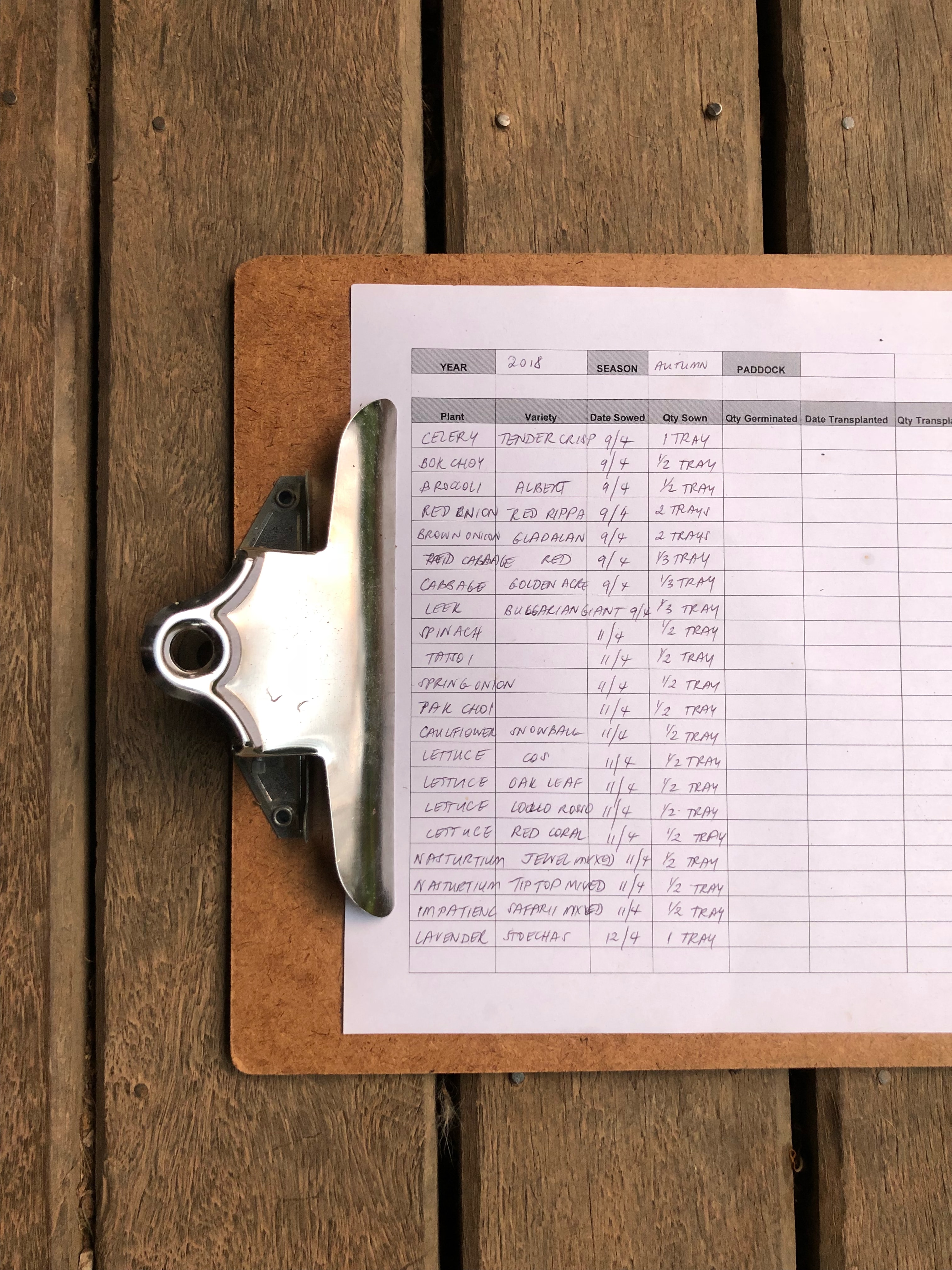

Clipboards

Invented around 1908 by George Henry Hohnsbeen, the clipboard known today is sturdy and consistent. Ranging from logistics, to banking, to large sporting events, clipboard management techniques are practiced in every industry. Even though clipboards are still used frequently today, they were not designed as a true management tool. With no immediate way to communicate written information to other managers or suppliers, the clipboard provides little help to supply chain managers besides a hard surface to write on when a desk isn’t available. Before desktop computers and the internet, communication existed solely on paper, but supply chain managers now have many options available to cut costs and improve the value of the supply chain.

Barcodes

In 1974, NCR Corporation developed the first UPC scanner. Since inception, the barcode and barcode scanner has revolutionized almost every industry in the world. Barcoding gave companies the ability to uniquely identify items electronically for the first time, a concept that is still being built upon. When used properly, barcodes allow visibility and traceability in the supply chain, but they also come with some major downfalls. One of the biggest downfalls of barcode technology is that it requires line-of-sight. Not every company sees line-of-sight as a critical downfall. Smaller companies can make do without line of sight depending on the amount of items moving throughout the facility. Large and medium size companies will see the most benefit from a change from barcodes to RFID.

RFID

First observed in 1973 and later optimized for the supply chain, RFID is able to fill in the gaps in supply chain management. Like barcodes, RFID provides managers the ability to uniquely identify each item on the facility floor, but then goes one step further in providing that information without requiring line-of-sight. This is critical in stages like packaging, shipping, and delivery. Usually packed together tightly on a pallet or in a box, items in transit make barcode reading extremely difficult.

Before a supply chain manager says no to changing management styles, there are two questions they should answer:

1. How well do they think the management style is working? For example, what is the on-time shipment to customer percentage rate for the supply chain? a. 0% - 60% b. 61% - 70% c. 71% - 80% d. 81% - 90% e. 91% - 99%

2. What do your current management techniques work well in comparison to? a. Manual Processes b. Clipboard Management c. Barcode Management d. RFID

If both answers are choices a – c, an opportunity exists to improve the supply chain management process.

The two biggest reasons that most people do not make the move to RFID are cost and being complacent. Managers who are able to identify problems with their supply chain, but are hesitant to proceed forward with RFID, should contact us about our RFID rental program. Our RFID rental program allows companies to test RFID equipment and tags against their current management process without having to make a commitment. If you mention this article when renting, you will receive a free custom RFID sample pack when your rental equipment ships.

Conclusion

If you have any questions about supply chain management with RFID or our rental program, contact us or leave a comment below.

If you would like to learn more about all things RFID, check out our website or our YouTube channel.

To learn more about RFID and supply chain management, check out the links below!