Active RFID vs. Passive RFID: What’s the Difference?

Updated on August 14, 2025

Introduction

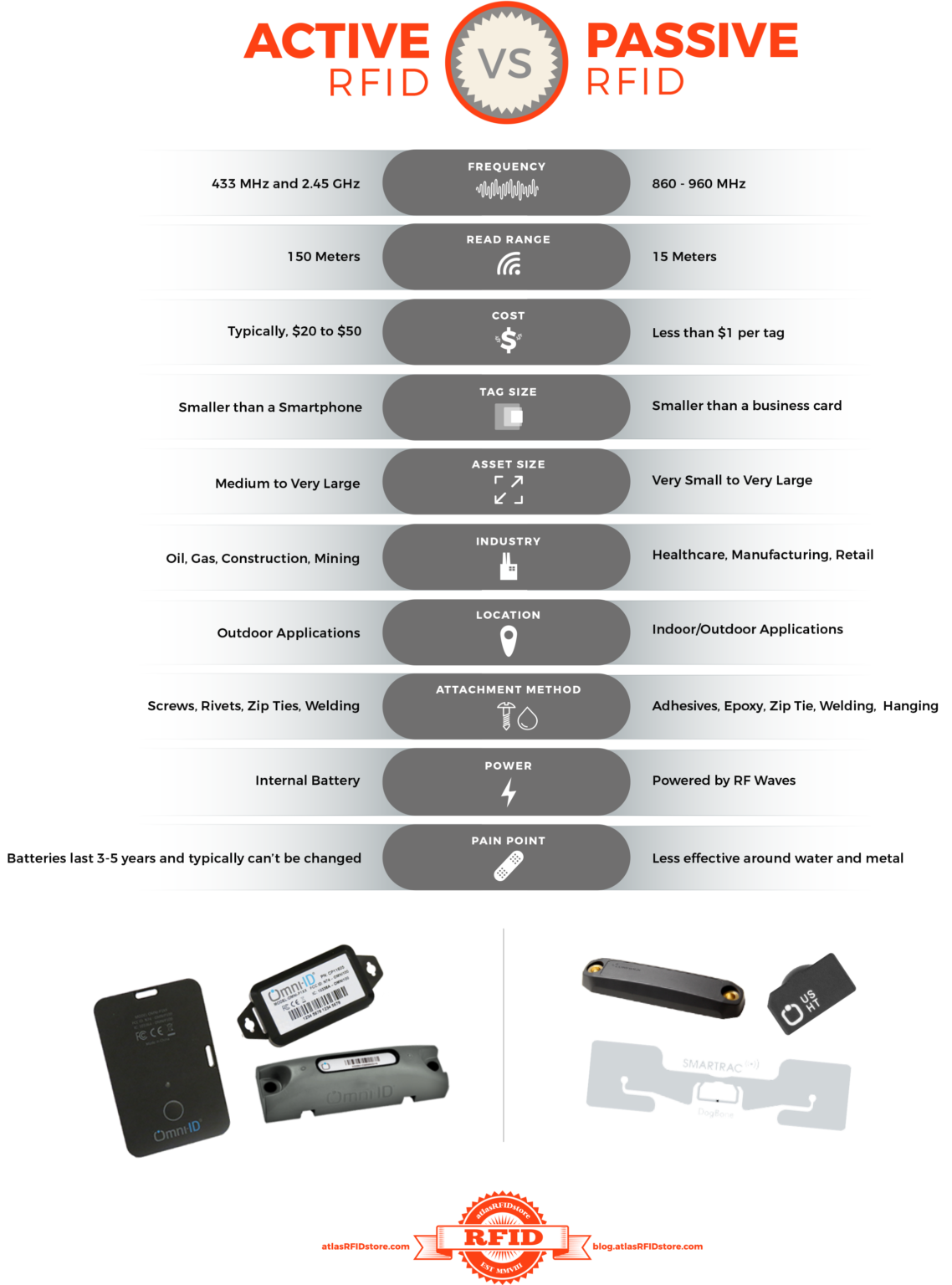

There are two kinds of RFID systems that exist- passive and active. If you're new to RFID, you might be wondering what the difference is between these types, and which one is best for your application. Below, we provide a short answer to these questions and more along with a more complex, long-form answer.

Short Answer

Passive RFID systems use tags with no internal power source and instead are powered by the electromagnetic energy transmitted from an RFID reader. Passive RFID tags are used for applications such as access control, file tracking, race timing, supply chain management, smart labels, and more. The lower price point per tag makes employing passive RFID systems economical for many industries. Passive RFID labels can be purchased for around $0.09 per tag and printed quickly and efficiently with an RFID printer and can be placed directly on an item.

Active RFID systems use battery-powered RFID tags that continuously broadcast their own signal. Active RFID tags are commonly used as “beacons” to accurately track the real-time location of assets or in high-speed environments such as tolling. Because active RFID tags rely on a battery, they do not have a long lifespan, and must be replaced every 3-4 years. Active tags provide a much longer read range than passive tags, but they are also much more expensive.

In-Depth Answer

Passive RFID

Generally speaking, three main parts make up a passive RFID system – an RFID reader or interrogator, an RFID antenna, and RFID tags. Unlike active RFID tags, passive RFID tags only have two main components – the tag's antenna, and the microchip or integrated circuit (IC).

As the name implies, passive tags wait for a signal from an RFID reader. The reader sends energy to an antenna which converts that energy into RF waves that are sent out into the surrounding area. The RFID tags receive the energy through the internal tag antenna, and then it travels to the connected IC. The RF energy allows the IC, or chip to turn on and modulate the energy with the information stored in their memory bank and then sends that information back out through the tag's antenna.

The modulated RF energy that is sent back to the RFID system is called backscatter. The backscatter, or change in the electromagnetic or RF wave, is detected by the reader (via the RFID system antenna), which interprets the information.

As mentioned above, passive RFID tags have no internal power source, and a standard passive RFID tag consists only of an IC and internal antenna; this basic structure is commonly referred to as an RFID inlay. The IC and tag antenna are placed on the tag material, typically PET plastic, and either finished with adhesive and/or a white-label face.

Countless other types of passive RFID tags exist on the market, but all tags generally fall into two categories based on form factor – inlays or hard tags. Hard RFID tags are durable and made of plastic, metal, ceramic and even rubber. They come in all shapes and sizes and are typically designed for a unique function, material, or application. One of the best examples of this is RFID laundry tags. They are made to be durable enough to withstand the high temperatures and rugged nature of the laundering process.

Groups of Passive Hard Tags

A few different groups work to further divide passive hard tags; however, some tags will exist within two or more groups.

High Temperature RFID Tags – Certain industries, like healthcare, pharmaceutical, and manufacturing, track the number of cycles that instruments undergo in punishing autoclaves. Specific passive RFID tags are designed to withstand extreme temperatures and accommodate for those types of applications, among others.

Rugged RFID Tags – Applications in outdoor environments or tough warehouses need a tag that can withstand snow and ice, dust and debris, or even the crushing forces felt under a tractor wheel. For these applications, a highly rugged passive tag is needed to make the application successful.

Size – Some applications have specific size constraints when tracking small or large items. Size is one of the more important questions to answer when choosing an RFID tag because there are many different sizes available.

Item Materials – If an application requires tracking metal assets, UHF metal-mount tags are typically the only way to get a reliable tag read, with a decent amount of read range. These tags are specifically designed to mitigate the problems UHF RFID faces around metal.

Embeddable RFID Tags – If tagging an item becomes a problem for specific applications due to significant wear and tear, embeddable tags can fit in small crevices and be covered in epoxy so the RFID tag is out of harm’s way. To learn more about how to embed RFID tags, read our article: Embeddable RFID Tags - What do I Need to Know.

A roll of Passive RFID inlays

Inlays

Inlays are usually the cheapest RFID tags costing as low as $0.12 per tag in high volumes, but the price does not affect the performance. These inlays are grouped into three main types:

-

Dry Inlays – An RFID microchip (IC) and antenna attached to a material or substrate called a web. These inlays look like they have been laminated and come standard with no adhesive.

-

Wet Inlays – An RFID microchip (IC) and antenna attached to a material, usually PET or PVT, with an adhesive backing. Most of the time these inlays are clear and can be peeled off their roll and immediately stuck on an item.

-

Paper Face Tags – These are essentially wet inlays with a white paper or white poly face with an adhesive backing. These are ideal for applications that need printed numbers or logos on the front for identification.

Passive RFID tags do not all operate at the same frequency. There are three main frequencies within which passive RFID tags operate. The frequency range, along with other factors, strongly determines the read range, attachment materials, and application options.

Below is a quick overview of the main three frequencies for passive RFID. For a more in-depth look, take a look at our ebook, A Guide to RFID Types and How They are Used.

-

125 - 134 KHz – Low Frequency (LF) – An extremely long wavelength with usually a short read range of about 1 - 10 centimeters. This LF frequency is typically used with animal tracking because it is not affected much by water or metal.

-

13.56 MHz – High Frequency (HF) & Near-Field Communication (NFC) – A medium wavelength with a typical read range of about 1 centimeter up to 1 meter. This HF frequency is used with data transmissions, access control applications, DVD kiosks, and passport security – applications that do not require a long read range.

-

865 - 960 MHz – Ultra High Frequency (UHF) – A short, high-energy wavelength of about a one meter which translates to long read range. Passive UHF tags can be read from an average distance of about 5 - 6 meters, but larger UHF tags can achieve up to 30+ meters of read range in ideal conditions. This frequency is typically used with race timing, IT asset tracking, file tracking, and laundry management as all these applications typically need more than a meter of read range.

As a general rule, higher frequencies will have shorter, higher-energy wavelengths and, in turn, longer read ranges. Moreover, the higher the frequency, generally speaking, the more issues an RFID system will have around non-RFID-friendly materials like water and metal.

Pros of Passive RFID:

- Smaller tags

- Much cheaper tags

- Thinner/more flexible tags

- Higher range of tag options

- Tags can last a lifetime without a battery (depending on the wear and tear)

To read more about Passive RFID, checkout our article - What is Passive RFID?

Active RFID

There are two main frequencies used by active systems – 433 MHz and 2.45 GHz. User preference, tag selection, or environmental considerations usually dictate which frequency to use for most applications. Companies generally favor RFID systems that operate on the 433 MHz because it has a longer wavelength enabling it to work a little better with non-RF friendly materials like metal and water.

Active RFID systems have three essential parts – a reader or interrogator, antenna, and a tag. Active RFID tags possess their own power source – an internal battery that enables them to have extremely long read ranges as well as large memory banks.

Typically, active RFID tags are powered by a battery that will last between 3 - 5 years, but when the battery fails, the active tag will need to be replaced. As the active tag market matures, replaceable batteries will be a cost saving option. The system’s functionality depends entirely on the type of tag chosen for the application.

Essentially, two different types of active RFID tags are available – transponders and beacons.

Transponders – In a system that uses an active transponder tag, the reader (like passive systems) will send a signal first, and then the active transponder will send a signal back with the relevant information. Transponder tags are very efficient because they conserve battery life when the tag is out of range of the reader. Active RFID transponders are commonly used in secure access control and in toll booth payment systems.

Beacons – In a system that uses an active beacon tag, the tag will not wait to hear the reader’s signal. Instead, true to its name, the tag will ‘beacon’, or send out its specific information every 3 - 5 seconds. Beacon tags are very common in the oil and gas industry, as well as mining and cargo tracking applications. Active tag’s beacons can be read hundreds of meters away, but, in order to conserve battery life, they may be set to a lower transmit power in order to reach around 100 meters read range.

Tasked with weathering harsh environmental conditions such as extreme temperatures and moisture, most active RFID tags are encased in a rugged shell. Because of the size of the enclosed battery, circuitry, and bulk of a durable exterior, active RFID tags are usually much larger than passive tags. Also, some active tags may have on-board sensors that track environmental parameters. These sensors can track moisture levels, temperature, and other key identifiers that a company can use for their application.

An example of a hardshell active RFID tag

All these additional features translate to increased costs for the customer, but the return on investment of a system may far outweigh the initial costs. The prices of active RFID tags range anywhere from $20 to $100+ depending on the tag’s ability to withstand harsh conditions and other key functional features of the tag. Given the required investment of an active RFID system, active tags are usually reserved for tracking high worth assets or for items where accurate location tracking is necessary to the success of the system. A few examples of these types of assets are pipes, cargo containers, and machinery.

While new applications for active RFID systems appear daily, these systems are usually used in the oil and gas industry, shipping and logistics, construction, mining, and high-value manufacturing.

Pros of Active RFID Tags:

- Extremely Long Read Range

- Increased tag abilities with partnered technologies (GPS, sensors, etc.)

- Extremely Rugged tag options

Size comparison between passive and active RFID tags

While both active and passive RFID technologies use radio frequencies to communicate information, each is very different, and likewise, possess different qualities well suited for varying applications.

Click Here for the Downloadable Version

Active vs. Passive RFID Tags Conclusion

Active and Passive RFID tags each serve unique purposes. Active RFID tags, with their internal power source, excel in long-range tracking and real-time location applications, making them ideal for large-scale asset management or vehicle tracking. On the other hand, Passive RFID tags are cost-effective, compact, and rely on energy from an RFID reader, making them perfect for inventory management, supply chain tracking, and retail use cases. Choosing the right RFID technology depends on factors like range, cost, and specific operational needs.

If you have any questions about active or passive RFID, please leave a comment below or contact us.

To learn more about all things RFID, check out our website or our YouTube Channel.

To read more about RFID basics, check out the links below!