A Tag, A Label, & An Inlay

Introduction

The technical jargon associated with learning about RFID can be a deterrent, or at least, daunting to someone considering working with this technology. When I first started over 6 years ago, not only did I mix up applications like asset tracking and access control, I even mixed up the basics, like frequently interchanging tag, label, and inlay. It wasn’t until a few weeks ago that I realized the appropriate terminology used to indicate the specific type of RFID tag is not only a common point of confusion for beginners, but for more experienced RFID professionals as well.

After my coworker had a few similar phone calls, she approached me with the idea to write about not only the differences in the verbiage, but the similarities as well – and why they matter.

Tag Terminology

Chip –An RFID chip is the size of a pin head, made from silicon, and is the “brain” of the tag where the data is stored. Also called Integrated Circuits, ICs, and microchips.

Antenna – A metal wire, metal foil, or printed metallic ink that transmits and receives radio waves.

Substrate – A thin layer of transparent material that holds the antenna and chip together.

Face – A thin layer of clear or white plastic, or paper that covers the antenna and chip.

Adhesive – Adherent used to attach a tag to an item.

Encasement – A covering that completely encloses the chip, antenna, and substrate that can be made of paper, plastic, PET, or similar materials.

Tag – Generic term that refers to any chip, antenna, substrate, and face combination. Also called transponder.

Inlay – Chip, Antenna, and substrate with or without adhesive.

Wet Inlay – Chip, Antenna, substrate, and face with adhesive.

Dry Inlay – Chip, Antenna, substrate, and clear face without adhesive.

Label – Chip, Antenna, substrate with adhesive, and a paper or white plastic face that can be printed on. Also called Smart Label or White Wet Inlays.

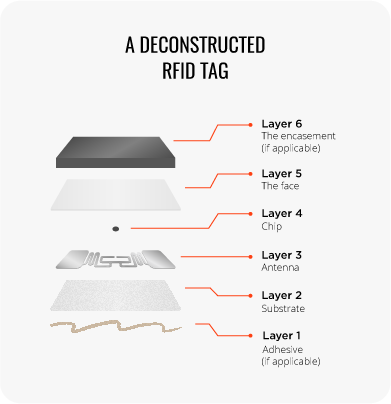

Tag Makeup

All RFID tags are comprised of the same four basic elements – a chip or integrated circuit (IC), an antenna, substrate, and a face. The chip is made up of electronic circuits and serves as the ‘brain’ of the tag. An RFID chip is usually made from silicon and contains four essential parts:

- A modulator that modulates and demodulates signals from the RFID reader.

- A power controller used to convert AC power to DC power and energize the chip.

- A logical unit which stores and executes communication protocols.

- Memory, used to store data, is typically broken out into three or four memory banks. (1)

A tag’s antenna is usually made from a metal wire, metal foil, or a conductive ink comprised of metallic particles. Antennas are made from metal in order to effectively conduct the energy between its receiving ends and the chip. Creating the antenna and attaching it to the substrate is done by etching, stamping, or printing, depending on the type of antenna. The antenna is then connected to the chip by one of two methods – flip chip, or wire-bonding. The flip chip method is accomplished by directly attaching the chip onto the antenna and then bonding the two using pressure or heat. The wire-bonding method, also called the strap technique, uses a fine strand of wire to connect the antenna terminals to the connection pads on the chip. The chosen connection method is dependent on the manufacturer, but most new RFID tags typically use the flip chip method because of how fragile the straps are in wire-bonding.

The substrate, a thin layer of transparent plastic containing both the chip and antenna, forms the basic structure for an inlay. Typically made of clear plastic, the face is then placed on top and secured, and the result is called an RFID tag, inlay, or dry or wet inlay – depending on if adhesive is applied.

At this stage, both wet and dry inlays can be sold to end customers or to label converters to create specific end products such as RFID labels, hang tags, badge tags, or hard tags – with the addition of a plastic encasement.

When It Matters

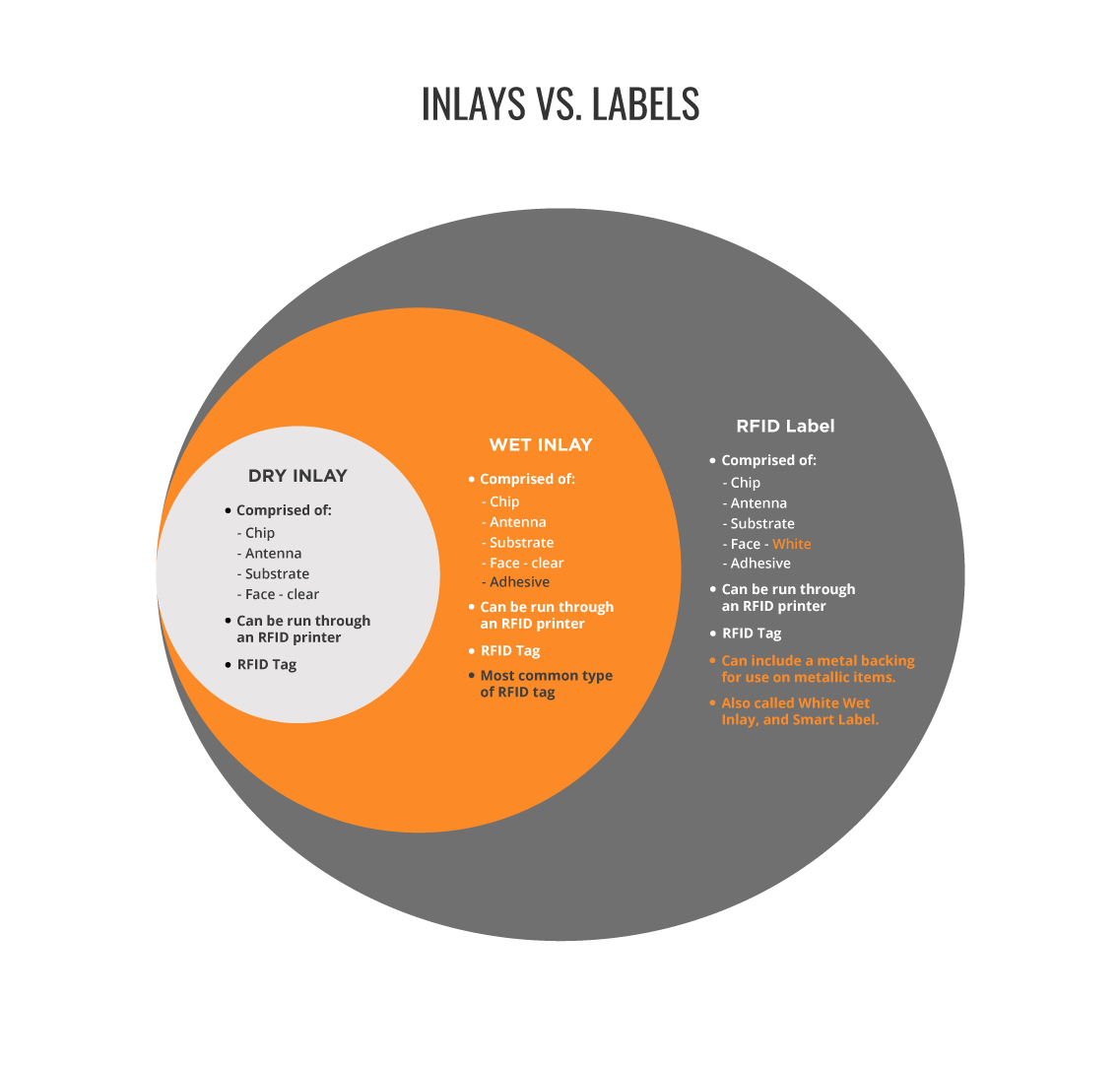

Because the term ‘RFID tag’ could be used to describe the combination of a chip, antenna, substrate, and face of any type or format, the important verbiage to examine is label, wet inlay, and dry inlay.

The most basic of the three is a dry inlay. Dry inlays are simply a chip, antenna, substrate, and clear face. Dry inlays are available on a roll, typically with no gap or black marks in between and no liner. While there is little to no waste, the absence of a liner and traditional gaps can cause complications when printing and encoding with an RFID printer. The reason for this is that printers typically calibrate the length between each tag based on the gap or black mark visible on the tags. Without these indicators, the RFID printer doesn’t know when one tag ends and another begins. If a roll of dry inlays does not have black marks, select printers can be set to calibrate based off the distance between two tag’s antennas as well.

To learn more about liners, gaps, or black marks – take a look at A Guide to UHF RFID Tags. To learn more about RFID printers, how to calibrate them, and their relationship with RFID tags – take a look at A Guide to RFID Printers.

Labels and wet inlays are the two most common types of RFID tags. Because of their low cost and addition of adhesive, they are ideal for most peel-and-stick applications. The difference between these two types of RFID tags is that wet inlays typically have a clear plastic face, and RFID labels have a white face, generally made from paper or plastic. While both wet inlays and labels can be used with an RFID printer, the printed text is much clearer on RFID labels. The white face of the RFID label provides a crisp, clean background for printed text, images, or 1D or 2D barcodes.

Conclusion

For more information about tags, labels, and inlays, comment below or contact us!

If you would like to learn more about all things RFID, check out our website or our YouTube channel.

To read more about RFID tags, check out the links below!

(1) - CompTIA RFID+ Exam RF0-001. Paul Sanghera. 2007 Syngress Publishing, Inc.