A Primer on RFID File Tracking

Introduction to File Tracking

Under the broad umbrella of Asset Tracking, file tracking is an application that involves tracking paperwork and files using RFID technology. File tracking systems are designed to reduce employee time spent maintaining and managing hundreds or thousands of files within a workplace. Many businesses currently use basic methods to manage files such as alphabetical filing, color-coded filing, or barcodes. RFID file tracking systems have become increasingly popular because they give employees enhanced visibility while freeing up time that was previously spent on inventory counts or searching for lost documents.

Benefits

Not every business still relies on old-fashioned paperwork, but it is prominent in certain fields like healthcare, legal, insurance, governments and more. Statistically speaking, employees spend nine minutes or more per work day looking for lost documents (or 38 hours per year 1). Nine minutes per day may not seem like much, but when the hours add up, that can equate to a large sum of money for the company. Wasting 38 hours per year 2, per employee can cost a business anywhere from $276 for a minimum wage employee, to thousands of dollars for higher level employees.

Besides monetary benefits, RFID file tracking has other benefits such as increasing organization in the workplace. An organized space not only helps employees, but also gives the business a professional appearance for clients. Losing a file or piece of paperwork can adversely affect a business’ reputation and may cause the loss of clientele. Online reviews can make or break a business in this day and age, which increases the importance of making a good impression on each and every client.

RFID Tags

RFID labels and wet inlays are small, thin RFID tags designed for an assortment of assets including paper and file folders. Some file tracking applications use HF (high-frequency) tags, but these tags have a read range of only a few inches, so finding them among thousands of files could take quite a while.

UHF ( ultra-high frequency) tags will provide increased read range - maximizing the chances of finding a tag. Additionally, UHF tags are less expensive than HF tags. A few different UHF wet inlays are recommended for file tracking applications.

Testing different tags is the only way to ensure the best tag has been selected for a specific system and application.

Encoding

When beginning the process of finding the right tag for an application, a sample pack of tags is recommended so that a variety of tags can be tested in the intended environment.

Each tag varies, and one important aspect to keep in mind is the pre-encoded EPC number on the tag. Some tags come with a unique, non-repeating EPC number, and others come with a number that is not unique. If the chosen tag comes pre-encoded with a non-unique number and is not manually re-encoded with a specific number, the RFID tag IDs have the possibility of repeating. This can be a problem when trying to find a specific file and several tag IDs are encoded to the same value as the one associated with the needed file. When encoding tags to specific identification numbers, a pre-encoded EPC number will not be a factor.

If more information is required on each tag besides the EPC number, the number of bits in the User memory bank will be important. As an example, a company may prefer less complex software that only associates a file name with an EPC number. In this case, the company could encode other necessary information such as last check-up date on the User memory bank if desired. For more information on RFID tag memory banks, please read Types of Memory in RFID Tags.

RFID Antennas & Cables

When using a fixed reader system, RFID antennas and cables should be chosen based on the type of system selected. For example, an RFID inventory system will generally use different antennas and cables than a large area tracking system. In general, circularly-polarized antennas are recommended for file tracking because the RFID tags on the files will be read at different angles, especially for portal setups. For inventory counts where all files are tagged in the same place at the same angle, linearly-polarized antennas can be used.

To learn more about RFID antennas, take a look at Circular Polarization vs. Linear Polarization: Which is the Right RFID Antenna. RFID cables connect the RFID reader to the antennas and are a key part of any RFID system.

The length and insulation rating for each will depend greatly upon the size and distance of your RFID system. In short, it is best to use shorter cables whenever possible due to the loss of RF energy that occurs along the length of RFID cables. If a longer cable is required, using a cable with higher insulation rating will help to reduce the amount of RF energy lost and ensure a stronger signal back to the reader.

To learn more about RFID cables, check out RFID Antenna Cables: Getting the Highest Performance Possible.

RFID Readers

Not all handheld RFID readers include a program that functions like a Geiger counter or metal detector to assist in finding specific RFID tags. Some companies will rely on this feature for finding RFID tags making it a critical requirement when browsing and purchasing an RFID handheld reader. Such a program is commonly referred to as a tag locator function, which is included on specific handheld readers usually for testing purposes.

These tag locator demo programs are built only for testing, and it is the manufacturers’ assumption that the reader will be used with software specific to the end-user’s application. The tag locator function is a very basic program,but a software developer can create a more user friendly program and incorporate it as a piece of a larger, more robust system.

Fixed readers do not come with any sort of tag locator functionality, but because fixed readers are not typically associated with isolating a single file, the lack of this feature will not impede progress. Fixed readers are more commonly used for mass inventory counts or reading tags when they pass through a portal.

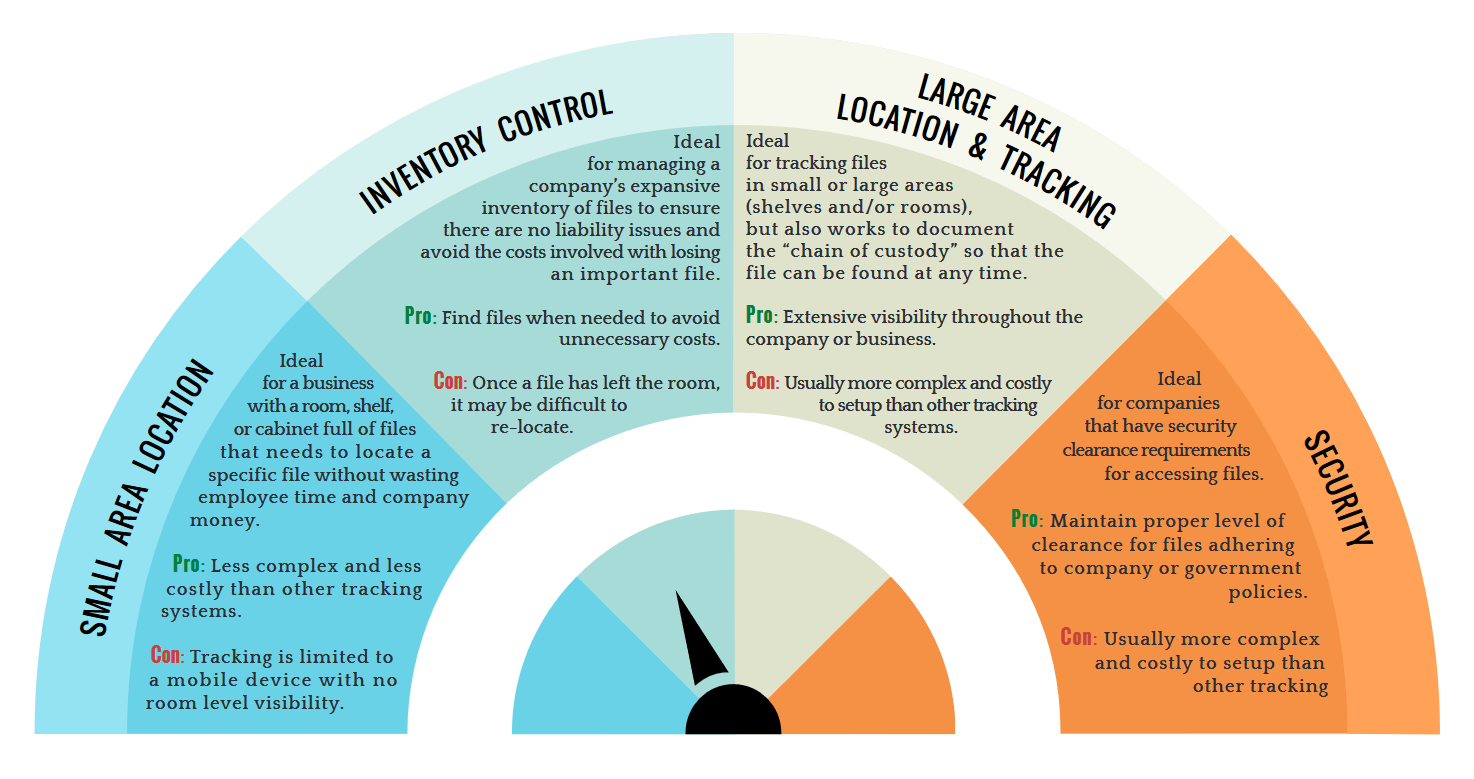

Types of File Tracking

There are many ways to classify file tracking systems, but one of the simplest ways is grouping systems by basic functionality:

Small Area Tracking

Small Area Tracking is locating files within a limited space such as a small room, cabinet, or shelf. This system is less costly than others, can be easily relocated if needed (e.g. a change in office or filing area), and can be used with a simple Excel document for associating RFID tag IDs with file numbers as the software component.

Hardware Setup:

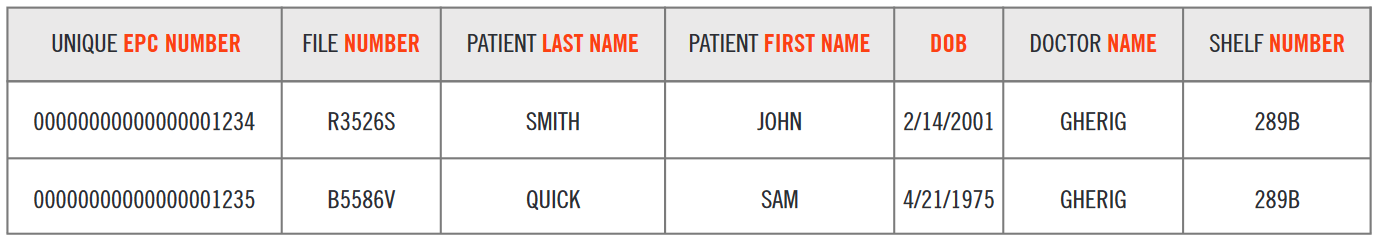

Getting started with a small area tracking system requires a handheld reader, RFID labels, and an Excel document or software. Each RFID label will either come pre-encoded with a unique EPC number or will need to be encoded with a specific number by the end user. The EPC number is then associated with the file name or number for searchability purposes. The sample Excel document below has been setup to reflect a simple document for a doctor’s office that associates the EPC number with the patient’s file number. When using this method, searching within the document for a keyword/number will bring up the file and the associated EPC number.

When the EPC number is typed into the handheld reader’s tag locator program, holding down the trigger starts the Geiger counter type functionality which beeps faster the closer the user gets to the specific RFID tag.

Inventory Control

Using an RFID File Tracking system for inventory control may be a more attractive solution for businesses that spend days or weeks performing inventory checks. Inventorying by hand not only takes critical employee time, but also can be skewed due to human error. RFID technology can take inventory control from being a monthly or yearly process to a daily routine only taking a few minutes to complete, which would also increase visibility within the workplace.

Hardware Setup:

Inventory control file tracking systems can be more costly than other systems because of the amount of files that need to be read during an inventory cycle. They also require more robust software so that inventory counts can be sent to a database and identify the file or files that are missing. Without software to manage the process, the EPC numbers that the handheld reader reads during an inventory count will not be stored or transferred to be processed.

File Tracking systems for inventory control can be setup several different ways depending on the amount of files to be inventoried.

Hardware Option 1: Handheld Reader

UHF tags can be used with handheld readers in a file tracking system because these tags have at least a couple of feet of read range. By slowly moving a handheld reader down a row of tagged files, inventory can be taken going row by row. See the video of inventory being counted using the ALH-9011 handheld reader and UHF tags.

Hardware Option 2: Fixed Reader & Shelf Antennas

Using a fixed reader with shelf antennas can take most of the effort out of doing walk-through inventory counts. By placing the files on the shelf antennas, the fixed reader can periodically inventory the tags. When a folder is removed, the software can accurately report which folder has been removed from which shelf.

Hardware Option 3: Fixed Reader Cart System

Similar to using a handheld reader,designing a mobile fixed reader system is a good way to take inventory by moving row to row. Affixing two to four circularly polarized antennas to an adjustable pole allows the user to slowly move the cart down the aisles to take inventory. This method involves much testing to ensure the antennas are set up and placed at proper angles and height to read the tagged files.

Large Area Tracking & Location

One of the mostly costly and complex systems to setup, large area tracking and location can find a file within a room, cabinet, or shelf; however, it also has the ability to create and maintain a chain of custody for each file that is tagged. A key aspect that the previous two types of file tracking systems lack is visibility outside the file room or specific area. Because this system is more complex than most, several different setup options are available depending on the customer’s environment and/or hardware preferences. This system can also be combined with any of the other three types of file tracking systems to create a more powerful file tracking solution.

Hardware Setup:

In order to create a chain of custody, the software must be able to recognize each employee, so employee badges with RFID labels are necessary for the success of this system. Each employee’s badge information as well as the RFID tag’s ID number will be associated in the software to document the employee’s movements with the files.

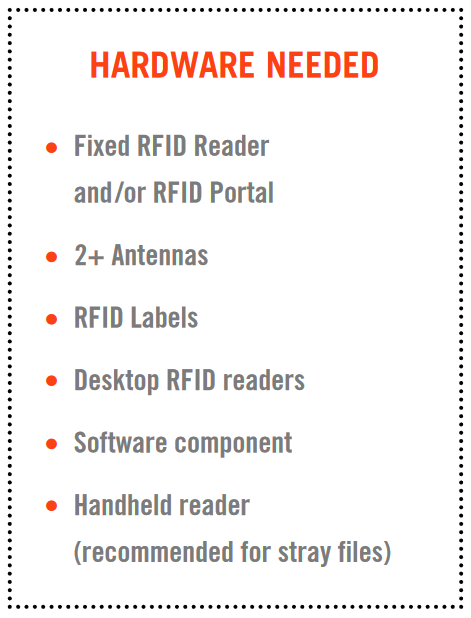

A Portal System at Every Entrance and Exit of the File Room:

To capture the movement of tagged files, an RFID system is required at every entrance and exit of a file room. A basic portal system using a fixed RFID reader and 2+ antennas can be used to capture tags as they pass through the portal. One issue of note is that the portal system alone cannot accurately report if a person taking a file is going in or out of the filing room. To mitigate this issue, incorporating the use of GPIO devices, such as light break sensors, will help to determine directionality (when paired with software logic).

Without any other hardware, the system only knows who has taken the file from the file room. With some companies, that may be enough information – for others, the chain of custody does not stop when the file leaves the room, and it isnecessary to know when the file reaches the employee’s desk and how long it is there.

A Desktop Reader at Every Employee's Desk:

By placing a low-cost desktop RFID reader at each employee’s desk, the software can document that the tagged filehas reached its destination. The desktop reader also adds increased visibility if the file travels from desk to desk, instead of from desk to file room.

Security

Determining clearance levels for viewing important documents is another type of file RFID tracking system. As with large area tracking and location, RFID labels are not only required to be on each file, but also on each employee badge. Complex software is necessary for this type of system because the employee badge and tag ID from the RFID label will need to be associated as well as the current clearance level for the employee. Once setup, the system can trigger a buzzer or alarm (through a GPIO device) that will sound when a file is taken without the proper clearance. Setting up this type of system will vary greatly depending on your software. Some software systems will have user-friendly touch screens for checking in and out, while others will be able to work with less complex hardware configurations.

Hardware Setup:

As mentioned previously, the hardware configurations will vary greatly depending on the software’s capabilities. Generally, all security hardware setups will need some type of portal system to track tags leaving the file room as well as a GPIO device to trigger an alarm (if needed). This portal system can be a pre-packaged portal, or readers and antennas installed in the frame of the doorway. Requiring more initial time and hardware, a check-in/check-out system could be accomplished by using an RFID reader to read ID badges and then allows the user to check out the required file. This type of system requires less automated processing than a system that relies on the portal system to scan the ID badge and file. When the portal scans both RFID tags, it sends the information to the software to make a quick decision regarding clearance levels requiring a more complex software solution.

RFID Software

Several RFID file tracking software providers exist on the market today with a packaged software solution. These software solutions have many different capabilities depending on the version that can help you find files, search file history, take inventory, and more. Some software programs associate the tag’s EPC number with the file information, and users can search by keyword for ease of use. Hiring a software engineer is a great option to ensure a system meets certain criteria that perhaps is not available in a pre-packaged software solution. Software developers are able to write applications that interact with the RFID readers and create databases and programs aiding in reducing time and effort spent finding lost files.

Additional Information

Tracking files with RFID can be extremely beneficial by saving money and time that was otherwise wasted locating lost files. Several different hardware and software setups are available that can provide different, unique results depending on what a company requires from its RFID file tracking system. To learn more about the benefits of a file tracking system, checkout more information on the subject:

To learn more about file tracking with RFID, do not hesitate to contact us for more information.