The Top 10 Most Asked Questions About RFID Printers

#1 How many tags can an RFID Printer print (per day)?

There are three main types of RFID printers – Industrial, Desktop, and Mobile. Printers are assigned to these categories based on factors like ruggedness, mobility, size, and bandwidth. Industrial printers can withstand a wide range of environmental conditions and can print around 10,000 RFID tags per day. Desktop printers print a lower volume of tags overall, around 500 or more per day, and are designed to be used indoors in a low-risk environment like an office. Mobile printers, as their name implies, are small, lightweight devices that can be carried around warehouses or large work spaces. Although extremely mobile, that same small size limits them to only printing, on average, around 200 or more tags per day.

#2 What types of materials can RFID printers print on?

Printers can print on paper both coated and uncoated paper, and plastic or synthetic label surfaces.

#3 Can I print metal-mount labels on any RFID printer?

No, metal-mount labels can only be printed on specialized printers that are optimized for metal-mount tags. These printers are calibrated according to precise measurements between the reader module, the print head, and the tag because of the increased thickness of metal-mount tags.

#4 What data an be encoded on a tag using an RFID printer?

Data must be encoded to RFID tags in a certain format using UHF Gen2 specifications. There is also a limited amount of data that can be stored on tags depending on the format used. Here are some quick facts about encoding formats and data quantities.

- The quantity of data that can be encoded on an RFID is typically between 8 – 64 Hexadecimal characters or between 4 – 32 ASCII characters (when using Hex to ASCII conversion).

- With Hexadecimal, there are 16 characters that can be used - 0 - 9 and A - F.

- With ASCII, there are 128 characters that can be used - the lower case and upper-case alphabet, numbers 0 - 9, and some special characters as well.

To learn more about Hexadecimal and ASCII encoding schemes, look at the article below.

#5 How do I choose a type of ribbon?

A few different types of ribbon can be used with RFID Printers – Wax Ribbon, Wax-Resin Ribbon, and Resin Ribbon. The type that is right for you depends on what material you are printing on and the level of quality needed for the image or text.

- At the lowest cost point is Wax Ribbon, which is commonly used on paper labels both coated or non-coated. Wax Ribbon produces a soft image that is, unfortunately, very susceptible to scratches and abrasions which generally leads to a shorter lifespan.

- Wax-Resin Ribbon is a mid-range selection both in price and image quality. It is typically used on coated paper labels with a glossy, smooth surface as well as synthetic labels. This ribbons allows for a longer lifespan because it is more resistant to scratches and abrasions.

- Resin Ribbon images have a longer lifespan because of the high quality and resistance level. This type of ribbon has a higher price point because it prints clear, sharp images and is recommended for synthetic labels and garment labels.

#6 How do I load ribbon into an RFID printer?

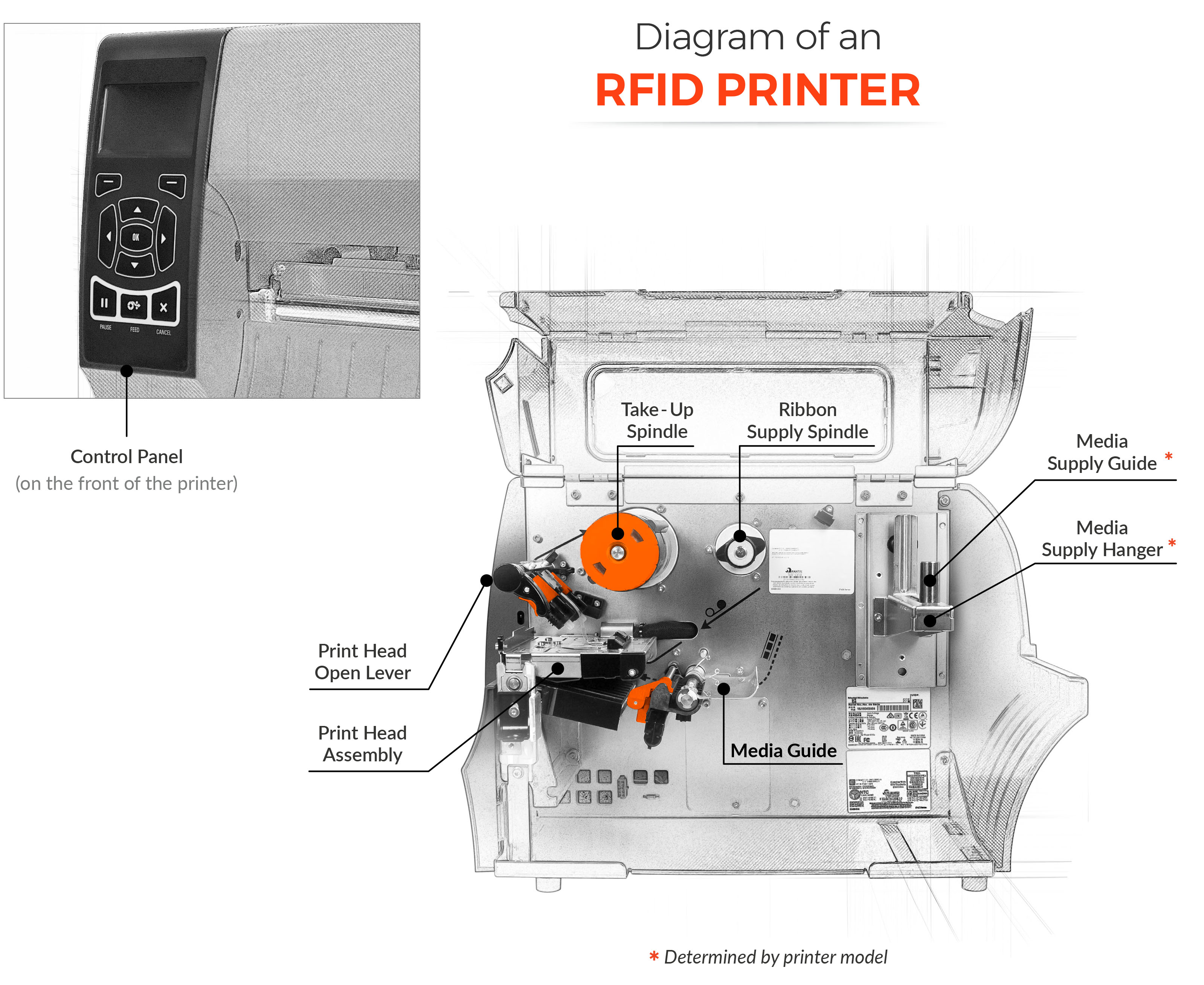

The printer ribbon is placed on the Ribbon Supply Spindle and the free end winds under the print head and loops up to the Take-Up Spindle. Typically, the free end is taped down and then wound back several times to secure it in place and tighten it against the print head. However, If the ribbon is not secure and is pulled free, or the ribbon runs out, the printer has a ribbon sensor in place to stop the printing and send an alert. Checkout the diagram below to identify these printer parts and learn how to load a ribbon.

#7 How many tags can be printed per roll of ribbon?

An average roll of ribbon for an industrial printer has an length of around 1400 ft (427 m) or 16,800 inches. The average RFID label’s length is 1-inch but can vary anywhere from half-an-inch to 6 inches or more. If you are using a roll of ribbon that is 16,800 inches and you are printing 1-inch long tags with an average break of 0.15 inches between tags, you can most likely print somewhere around 14,000 tags with one roll of ribbon (this number was rounded down from 14,400 to 14,000 to account for any ribbon wasted in the rolling or re-rolling process).

Note: This is an estimate and should not be used as a specific measurement.

#8 What is involved in the printer calibration process and how is it done?

Printer Calibration is the process of setting up the printer to be able to print and encode your RFID tags. Generally, it involves placing the ribbon and securing it, placing the tags and securing them, and then performing an RFID calibration either automatically through the on-screen navigation or manually by consulting a specific tag’s measurements. In order to print and encode RFID tags, a printer must be calibrated for each specific tag.

Printer calibration can be done automatically through the printer interface, or manually if the automatic interface isn’t performing properly. To watch both processes and learn more, check out the videos below.

Automatically Calibrating & Manually Calibrating RFID Printers

#9 Why are RFID printers expensive?

RFID Printers are complex devices that house RFID reader(s) and antenna(s), and a good bit of moving parts that work in sync in order to encode and verify RFID tags at a high speed. Alongside of the embedded RFID hardware is high-quality printing equipment, ensuring pictures, text, and barcodes appear as close to the on-screen proof as possible. In addition, printers have an abundance of firmware and tag specifics loaded onboard in order to make calibration and use as user-friendly as possible. Complex engineering goes into the design, prototyping, testing, and firmware development.

In addition to the typical features available on RFID printers, some printers have added usability features as well, such as Bluetooth and Wi-Fi connectivity, to ensure that connecting to and communicating with an RFID printer is as convenient as possible.

#10 What software can be used with RFID printers?

Communicating with RFID printers is usually done either by sending raw commands from the computer, or by using an out-of-the-box software, such as BarTender. Sending raw commands is not recommended for a large quantity of tags or as a long-term solution. It is typically only used to test out the printer before purchasing a software product or for a quick print of a few tags.

Out-of-the-box software has templates that you can follow to make the printing and encoding process easier and quicker. BarTender and Zebra both have quality software programs that make the process user-friendly, no matter if you are placing custom graphics on tags, or just simple human readable information. Another option is to create a custom piece of software that integrates with other software within a facility. Although this is less-common, printer manufacturers typically provide a printer’s API specifically for engineers to design custom software to work with their printers.

Conclusion

For more information on RFID printers take a look at the following eBook, comment below, or contact us!

To read more about RFID printers, check out the links below!