GS1's EPCIS Standard: What It Is & How To Use It

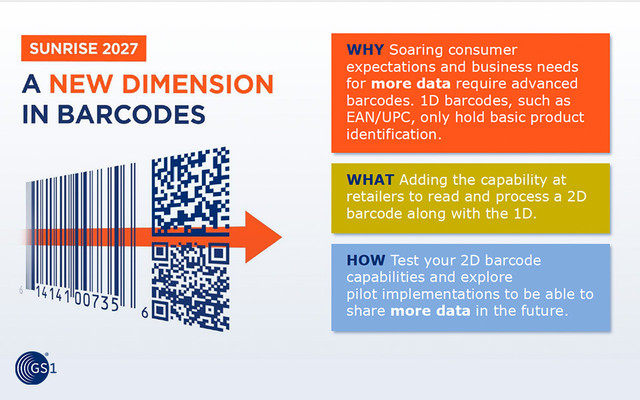

Supply chains have become increasingly complex. Products move through multiple facilities, transport partners, and data systems before reaching a customer. At the same time, retailers and brands are placing a higher priority on visibility, traceability, and accuracy. This is especially true with the rise of item-level RFID tagging requirements from major retailers. To support this level of shared visibility, companies need a common language for describing what is happening to their products and when. That is where GS1’s EPCIS standard comes in.

What is EPCIS?

EPCIS stands for Electronic Product Code Information Services. It is a GS1 standard that allows businesses to capture and share event data about the physical movement and status of products as they move through the supply chain.

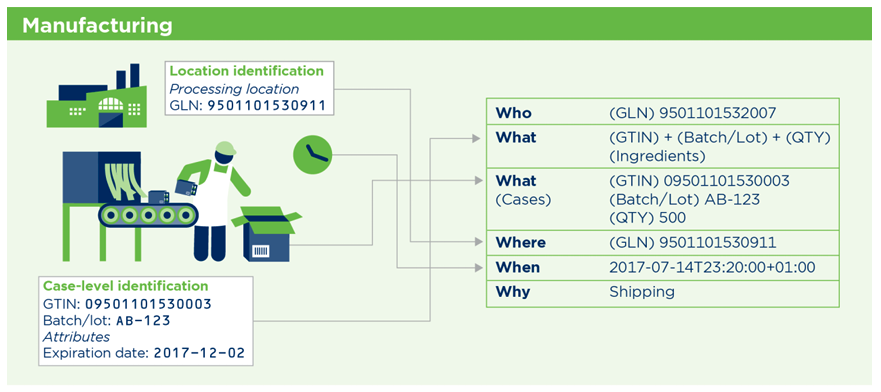

The four questions every EPCIS event answers

- What product or item was involved

- When the event happened

- Where it happened

- Why it happened (the business context)

For example, if a pallet is packed at a manufacturing plant, an EPCIS event records the items on the pallet, the time of packing, the location, and the business step such as “packing” or “shipping”.

EPCIS creates consistency. If every trading partner uses the same structure to describe events, systems can exchange information without custom formatting or one-off integrations. This improves collaboration, accuracy, and compliance.

Why Is EPCIS Valuable?

Visibility and Traceability

EPCIS provides a shared record of how products move through the supply chain. This helps answer questions like: Where was this item last seen? When did this pallet leave the warehouse? Which customer received these serialized units?

Regulatory and Retailer Compliance

Industries like pharmaceuticals and food require traceability for safety. Meanwhile, many retailers expect suppliers to support item-level accuracy programs. EPCIS helps create the data foundation needed to meet both needs.

Improved Inventory Accuracy

When EPCIS is paired with item-level data capture methods like RFID, businesses get a near real-time understanding of inventory. Better accuracy means fewer stockouts, fewer shipping errors, and better forecasting.

Stronger Partner Collaboration

Because EPCIS is a global standard supported by GS1, it works across business systems and across countries. Suppliers, distributors, and retailers can exchange event data without reinventing the wheel.

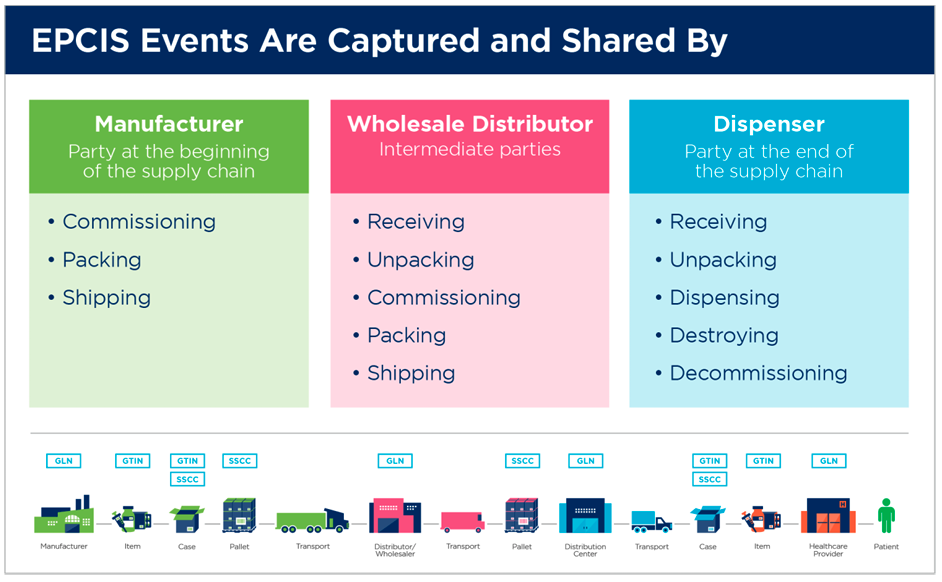

How EPCIS Works in Practice

To use EPCIS, a company identifies the important points in its supply chain where product movement should be recorded. These could include production, packing, shipping, warehouse receiving, store receiving, or even item-level movement on the retail floor.

At each of these points, systems capture an event and store it in what is called an EPCIS repository. These events can later be queried by authorized partners. The newer version of the standard, EPCIS 2.0, also supports modern formats such as JSON and API communication, which makes integration easier for today’s systems.

In many cases, EPCIS works hand in hand with RFID scanning, barcode scanning, or automated sensor systems. EPCIS does not dictate how you capture data—it simply standardizes how you describe and share it.

Common Event Types to Model

- Object Event: What happened to specific EPCs (e.g., items scanned at receiving).

- Aggregation Event: How items are grouped (e.g., items → case → pallet).

- Transaction Event: Links events to business transactions (e.g., PO, ASN, invoice).

- Transformation Event: Inputs converted into outputs (kitting, rework, pack/unpack).

How Your Organization Could Use EPCIS

- Identify the use case. For example, improving shipping accuracy or supporting a retailer’s visibility requirements.

- Confirm identifiers. Make sure your products and locations are using GS1 standards like GTIN and GLN. These are the building blocks for EPCIS.

- Map key supply chain events. Decide which events are meaningful to record, such as carton packing or outbound shipment.

- Choose systems that support EPCIS. This could include your RFID software, warehouse management system, or a standalone EPCIS repository.

- Start small and expand. Begin with a pilot product or customer. Validate, refine, and scale.

Pro tip: Pair EPCIS with reliable product and location identifiers (GTIN, SGTIN, GLN) and automated capture methods (RFID/barcodes) to turn real-world movements into structured, shareable events that all partners can understand.

Sample Roadmap & Success Metrics

- Pilot (30–90 days): One site, one product family, outbound accuracy; KPI: >99% ASN‒shipment match rate.

- Phase 2: Add receiving and store inventory events; KPI: Cycle Count Shrink < 2%.

- Scale: Roll out to additional customers and regions; KPI: On-Time In-Full (OTIF) +3–5 pts.

Conclusion

EPCIS gives businesses a consistent way to describe and share what happens to products across the supply chain. With retailers and industries demanding more transparency and accuracy, EPCIS is becoming a foundational tool. Whether your goal is compliance, efficiency, or visibility, adopting EPCIS can help you build stronger data and stronger relationships across your supply chain. Learn more about GS1's EPCIS on GS1's website.

You May Also Like