3 Reasons You Should be Tracking Your Returnable Assets

Introduction

If your company ships items that are too heavy, bulky, or in large quantities to ship through normal channels like UPS or FedEx Freight, then you understand the typical problems associated with shipping on pallets, trays, bins, or racks. When companies purchase these items, they have to decide if they want to purchase reusable, plastic or metal shipping assets, or purchase disposable wood or cardboard items. Using wooden pallets is the most common way to ship large quantities, but with the wave of environmental concern, especially reducing waste, reusable plastic pallets are becoming more appealing. Because plastic pallets cost more, it’s important for companies to view these as reusable assets instead of simply a means to an end. Here are 3 reasons that you should be using RFID to track these returnable assets.

#1 Save Money While You Make Money

While your business is booming, and more and more orders come in, the last thing that you want to be worried about is purchasing more shipping assets. If a customer doesn’t return a reusable asset, you might as well deduct the cost of a new pallet from this month’s bottom line profit. Instead of calculating the loss, you could contact that customer and ask them to return it.

#2 Create (and Enjoy) a Chain of Evidence

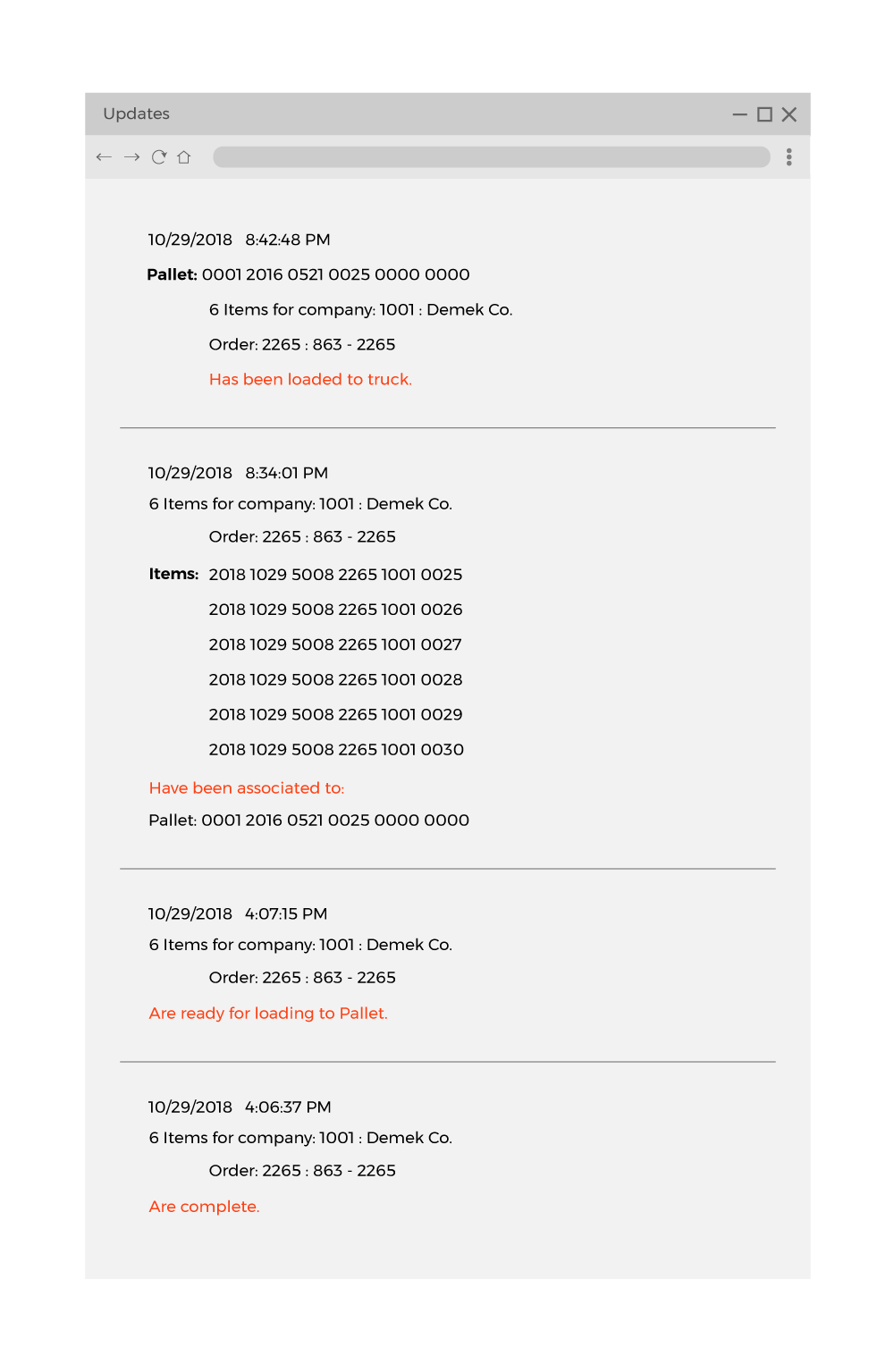

What happens when you know which customer didn’t return a shipping asset, but they plead not guilty? With a chain of evidence provided by hard data, you can provide proof and ask for it to be returned or bill them for the lost asset. The read data for each pallet can be stored in a database, so it’s even possible to know where that pallet was on this day, 2 years ago.

#3 Make Informative Decisions

Over time, all the reads can add up to a lot of interesting data. This data can help you make decisions like when to add more reusable pallets to the supply chain or how to allocate these assets so you can be prepared for the shipment of a large order. You can also get information like which customer takes the longest to return pallets, how many a customer has at one time, and when to reach out to a customer about a late return.

By tracking reusable shipping assets, you save money, create a chain evidence, and use new data to make informative decisions for your company.

What Does a System Look Like?

An RFID system for Returnable Assets, or Returnable Transit Items (RTI), starts with tagging the returnable items typically with rugged RFID tags. There will be a lot of movement in the shipping process that, when coupled with large machinery for loading and unloading, means there is high potential for scraping or bumping of these assets. Additionally, many RTIs are exposed to extreme weather – heat, cold, wind, and heavy rain or snow. A rugged RFID tag for this application will need to be able to withstand these potential obstacles without being damaged or falling off.

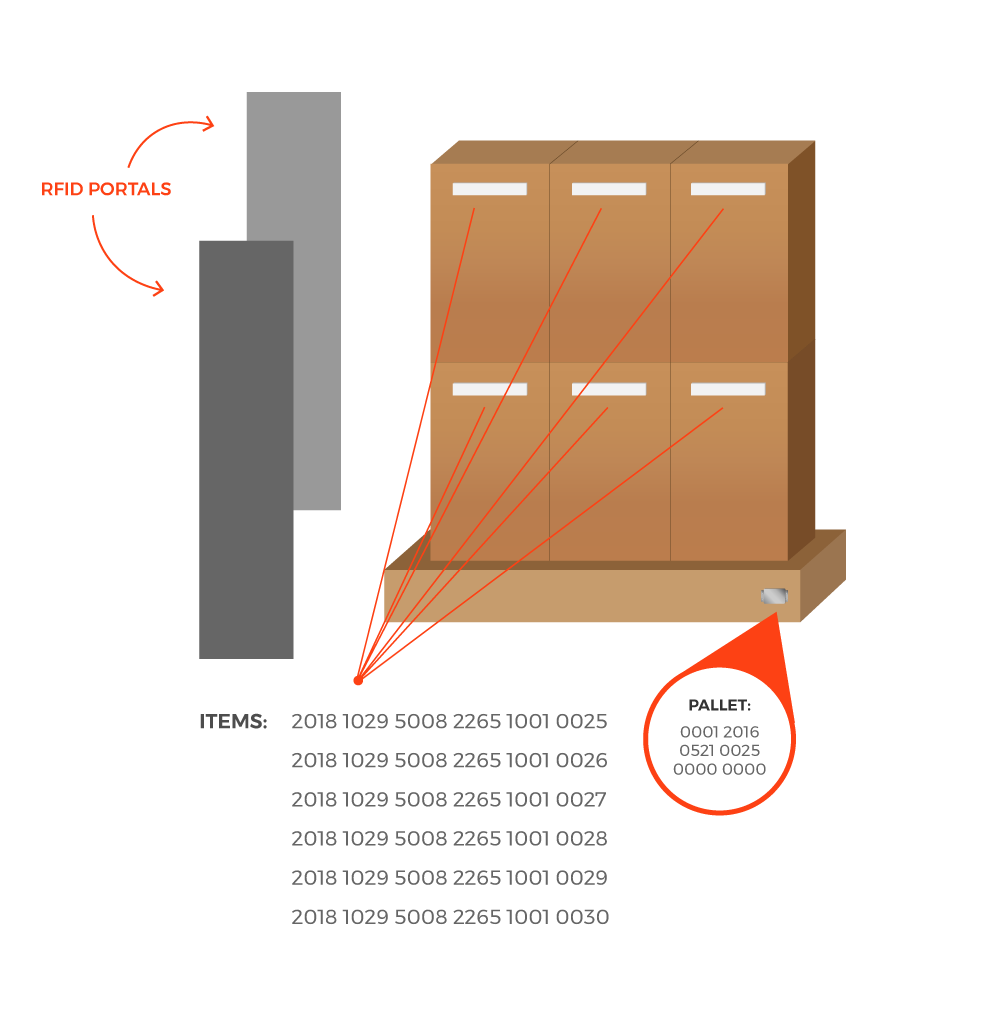

The RFID hardware may be handheld RFID readers that check in and check out the returnable assets, or portals can be installed at dock doors using fixed readers and antennas, or gateways. With the portal setup, the application has the added value of being hands free for reading RFID tags and associating them to a particular shipment or order.

Beyond Returnable Transit Item Tracking

Once RTIs have been tagged and a system has been setup to track them, you can take advantage of the existing RFID infrastructure to tag and track other inventory or assets. Many times, the items that reside on the returnable asset can be tagged as well. Using software, when the returnable asset is read, it can be automatically associated with RFID tags on the items being shipped. Each time the RTI is subsequently scanned, you’ll have insight into exactly where the inventory or assets are throughout the system. In addition, the shipping trailers can be tagged and associated with the loaded pallets when they get close to the portal. As systems are installed at other locations and networked together, you can track inventory and assets throughout your entire supply chain.

Conclusion

For more information on RTI applications and all things RFID, comment below or contact us!

If you would like to learn more about all things RFID, check out our website or our YouTube channel.

To read more about asset tracking, check out the links below!